The Heat

Exchanger Theory article provides you with an introduction to the

fundamentals of a heat exchanger and will be useful to understand the concept

of heat exchanger inspection.

To describe this

Theory, you may know we need to heat or to cool process fluids in industrial

plants to facilitate process reactions. So we need to use heat exchangers

either to reduce the temperature or increase the temperature.

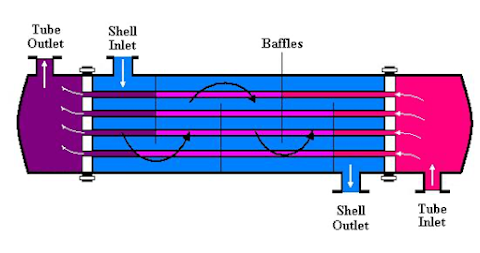

In most heat

exchangers, two fluids are exchanging their heat without direct physical

contact to avoid mixing. This is called indirect heat transfer.

Cooling water

temperature in a hot area is normally above 25 degrees centigrade, and it

depends on the atmospheric and climate conditions. To reach the range of 1 to 5

degrees centigrade, we need to use chilled water, which is already cooled by a

refrigerant.

To reach the

sub-zero temperature, we need to use refrigerant fluid alone, such as R-11 or

propylene. For heating purposes, the mechanism is similar to cooling. We can

use hot intermediate fluid such as hot water or steam and even other hot

process streams.

To proceed on the

heat exchanger theory, we need to know that the meaning of the following

terminologies:

Sensible Heat

Sensible heat is the amount of heat that a

material can exchange without changing its phase. For example, water at 25

degrees centigrade enters the heat exchanger and absorbs the process fluid heat

and exits from the heat exchanger at 35 degrees centigrade.

What is latent Heat?

The latent heat is the amount of heat

transfer that a material exchanges during the change from the liquid phase to

the vapor phase.

Referring to the above definition we are

using saturated steam in heat exchangers, the saturated steam is converted to

liquid and the released heat will heat our process fluid.

Indirect heat transfers are done in

different heat exchangers such as coolers, heaters, reboilers and condensers.

We are calling it

indirect because the two fluids during the heat transfer process are not mixing

together; the heat transfer is done through a metallic surface.

In the above, the

heat exchanger that we are using to eliminate latent heat is called a condenser

and the one that is used to supply steam and heat to the distillation tower is

called a reboiler. We will discuss them in detail in the coming paragraphs.

In all of them, we

are using an intermediate fluid for heat transfer. For the condenser, it is

cooling water, and in the reboiler, it is steam.

To Know More Read Full Article Here: https://sa179tubes.com/the-theory-behind-heat-exchanger/

.jpg)

Comments

Post a Comment