Compact Heat Exchanger

Generally, compact

heat exchangers are used in heat integrating processes and provide

advantages over shell-and-tube heat exchangers, such as compactness, large

surface area per volume ratio, low temperature differential, and can be applied

as MHEX.

Compact plate-fin heat exchangers are one type of compact exchanger, and

they are normally used in MHEX systems because they have the ability to handle

a large number of hot and cold streams in the same unit. However, the MHEX

structure is complex because it contains many channels for a number of hot and

cold streams to flow through an interaction between them.

Picon-Nunez et al. (1999) demonstrated a methodology for designing

compact plate-fin heat exchangers with the objective of minimizing pressure

drop. A thermo-hydraulic model was developed and the volume performance index

(VPI) corresponding to Reynolds number was used to select the best fin surface.

According to Reynolds number assumptions, fin selection could not

provide effective results. Picon-Nunez et al. (2002) then proposed the thermal

design of a multi-stream plate-fin heat exchanger. To analyze the relationship

between volume, heat transfer coefficients, and pressure drops, they developed

composite curves related to enthalpy intervals and used a thermo-hydraulic

model. A new design algorithm for counter-current plate-fin heat exchangers was

proposed by Guo et al.

(2015). Basic fin geometries were treated as continuous variables to

reduce computational time compared to the discrete design problem from previous

work, and thermal hydraulic performance was applied together with it to minimize the total volume.

In this study, we present a methodology for designing multi-stream

plate-fin heat exchangers by considering pressure drop utilization, optimizing basic fin geometry and minimizing the total volume of the exchanger by using

uniform block heights and widths across all block sections.

In the chemical process industry, heat exchangers are used for both

heating and cooling. CHEs are designed for efficient heat transfer from one

medium to another, with large heat transfer areas-to-volume ratios (minimum 300

m2/m3), high heat transfer coefficients (up to 5000 W/m2 K), small flow

passages, and laminar flow.

CHEsare often used to achieve large heat rates per unit volume,

especially when phase, composition, temperature, pressures, density, viscosity

and other physical properties (Shah et al., 1990). A section on compact and

non-tubular heat exchangers can be found in the 8th edition of Perry’s Chemical

Engineers’ Handbook (Green and Perry, 2008).

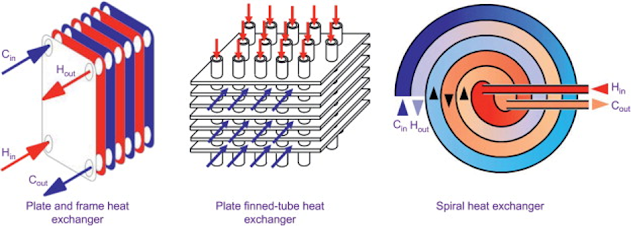

The following are the most common types of CHE:

Plate heat exchangers (PHE) use metal plates to transfer heat between

two fluids over a much larger surface area. The thin, corrugated plates used in

PHE are either brazed, welded or gasketed together depending on the

application. As a result of the compression of the plates in a rigid frame,

parallel flow channels with alternating hot and cold fluids are formed. Adding

or removing plates from the stack increases and decreases heat transfer area.

Plate-fin heat exchangers (PFHE) transfer heat between fluids using

finned chambers and plates. In a PFHE, corrugated sheets are separated by flat

metal plates which form a series of finned chambers. A series of hot and cold

fluid streams flow through alternating layers of the HE and are enclosed by

side bars. Additionally, the fins increase the structural strength of the PFHE,

allowing it to withstand high pressures while providing extended heat transfer

areas.

In addition to gas and liquid, PFHE can operate with any combination of

two-phase or three-phase fluids. Moreover, it can accommodate the heat transfer

between multiple process streams by using a variety of fin heights and types as

different entry and exit points for each flow.

To Know More Read Full Article Here: https://sa179tubes.com/compact-heat-exchanger/

#SA179 #StainlessSteelFabrication #design #steel #art #garden #gardendesign #rust #gardening #sculpture #metal #welding

.jpg)

Comments

Post a Comment